Applications

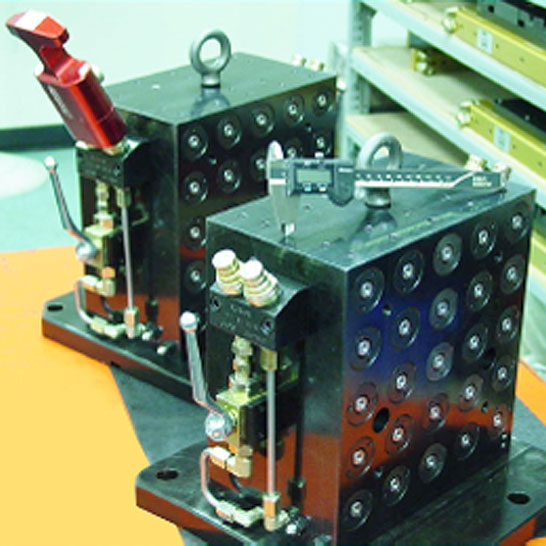

Workholding

APPLICATION:

Hold objects in place with immense pressure.

SOLUTION:

The two P901 pumps work together perfectly to reach the required holding pressure and automatically stop when the pressure is reached. Allowing for clamps and vises to sustain pressure and achieve fast clamping times.

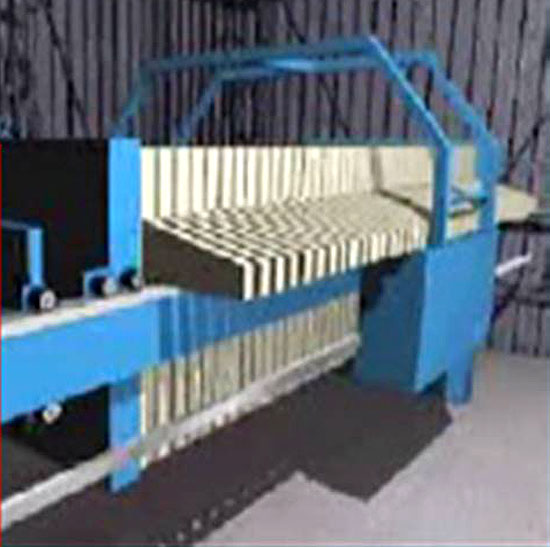

Filter Presses

APPLICATION:

Maintain a sealed column of screens during the filtration process.

SOLUTION:

The P901 and P820 pumps can hold pressure for weeks and months. Both pumps allow for fast approach speeds and quicker closing times.

Actuating

Valve Gates

APPLICATION:

Pressing hot plastic into molds before setting requires rapid opening and closing.

SOLUTION:

The P820 range ensures sufficient power for the gates to open quickly when required. Hydraulic solenoid valves direct the flow instantaneously to each valve inside the mold.

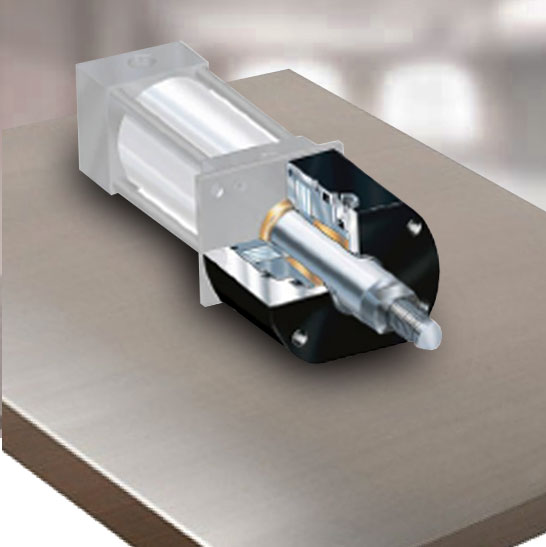

Cylinder

Rod Locks

APPLICATION:

Applying pressure to hold tables after indexing.

SOLUTION:

Hydronic’s P901 Model ensures pressure is always available for instantaneous operation and there is no noise between actuation. Hydraulic locks are pressurized, and thin steel membranes expand to grip the rod without damage.

Positioning

Spring Loaded

Cylinders

APPLICATION:

Feed mills require a constant force on a spring-loaded roller to maintain the correct gap for cereals to be shaped consistently.

SOLUTION:

The P820 double acting pump allows for energy cost saving because virtually no compressed air is lost during the cpressure sustaining cycle.

Actuating

Expanding Mandrels

and Chucks

APPLICATION:

Holding devices such as mandrals and hydraulic chucks need constant pressure to clamp parts during machining.

SOLUTION:

Small chucks can use the P720 range. While larger mandrels and chucks would need greater flow rates of the P820 range. Hydronic pumps can generate and sustain pressure with spindle oil and coolant while generating no wasted heat.